Distillery Feasibility Studies

See the full picture before you commit to bricks, copper and cash.

Building a distillery is a big commitment. There are exciting bits – new make flowing, visitors on site, bottles on back-bars – and there are the less glamorous bits: power upgrades, boiler choices, access rights, planning risk and cashflow.

Our feasibility studies are designed to bring all of that into focus early. We look at your ambition, your site and your numbers together, so you can make informed decisions before you lock anything in.

What we cover

-

Vision, brand & commercial intent

We start with the “why”. Is this about a flagship brand home, a local craft producer, expanding an existing whisky business, or a completely new venture? We explore how the distillery fits into your wider plans, who you want to attract, your price point ambitions and the part hospitality might play.

-

Site, constraints & context

Next, we interrogate the site. We review access, neighbours, buildable areas, planning and heritage context, topography, water and landscape. We also look hard at utilities – power, water, drainage and fuel – because these can quietly define the project before you’ve even started.

-

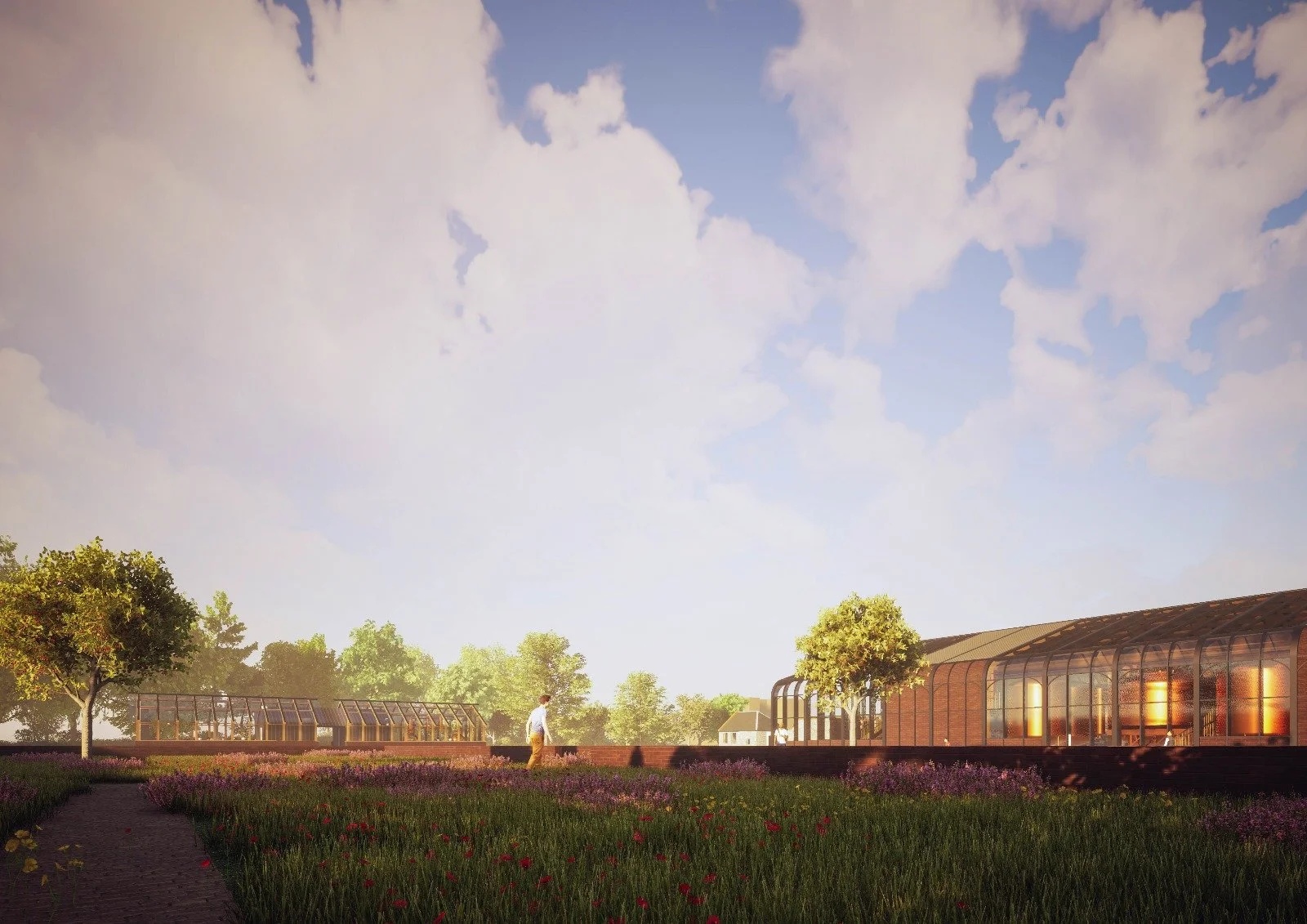

Masterplanning & overall layout

We then sketch how everything fits together: where the main distillery sits, how production, visitors and back-of-house relate, how vehicles move, and where future phases could go. The result is a clear big-picture plan for the site.

-

Visitor experience, wayfinding & safety

A distillery visit is a journey. We design that journey: arrival, main routes, types of visit, hosting models, key viewpoints and sensory moments. At the same time we keep an eye on wayfinding, public vs private zones, separation of people and vehicles, and emergency routes, so the site feels welcoming and safe.

-

Production concept design

Room by room, we look at the process flow: grain intake, milling, mashing, fermentation, distillation, cask handling and plant. We consider space, height, access, ventilation and drainage, the implications of likely equipment sizes, staff routes, future capacity, visitor sightlines and compliance.

-

Architecture, character & “look and feel”

We begin to define what the distillery should feel like. That includes overall form and silhouette, massing, material palette and the atmosphere of key spaces such as the still house and tasting areas. We’ll often use simple visuals and mood boards to test how the building might quietly echo your brand and packaging.

-

Sustainability, energy & long-term operation

We explore practical sustainability: energy and water strategies, building fabric performance, operational efficiency and options for future upgrades. The aim is not a badge on a brochure, but a distillery that’s efficient, resilient and affordable to run.

-

Cost, programme & roadmap

We bring it all together in numbers and time. You’ll receive an outline capital budget, key cost drivers, indicative programme, phasing options and a simple cashflow picture. We’ll also set out the next steps – from planning strategy and surveys to when to engage process engineers and other specialists.

How much does it cost?

How long does it take?

We offer our feasibility studies on a tiered fixed-price basis based around the size of production from Micro/Farm Distilleries up to Production capacity over 5m LPA.

Generally we will work with each clients desired timelines - it’s important to give yourself enough “thinking time” when you are setting the direction of a project so we would recommend three months as a solid guideline.