Feasibility for Existing Distilleries

Evolve your distillery without breaking what already works.

Sometimes the hardest distillery projects aren’t the new builds – they’re the ones where you’re already producing, already welcoming visitors, and trying to work out how to take the next step without disrupting the day job.

This feasibility study is for distilleries who want to increase capacity, sharpen their visitor offer, or untangle a site that has grown bit by bit over the years. We look at what you have, what you want to change, and how far the site can realistically be stretched.

What we cover

-

Current position & future ambition

We start with where you are now: production volumes, tour numbers, pinch points and pain points. We then map where you’d like to get to – from capacity and product mix to visitor expectations and price points – and agree what mustn’t be lost along the way.

-

Operational review: how the site really works

Because you’re already up and running, we can learn a lot from reality. We map process and people flows, look at back-of-house spaces, review safety and compliance concerns, and identify patterns in the “work-arounds” your team have developed. This shows us where the current layout is quietly helping – and where it’s holding you back.

-

Site, constraints & capacity for change

Next we test how far the site itself can go. That includes remaining buildable areas, opportunities to repurpose existing buildings, planning and heritage context, neighbour relationships, and headroom in utilities and access. The outcome is a realistic envelope for what ‘more’ might mean in your particular setting.

-

Production expansion options

We look at how to unlock more spirit without turning the place into an obstacle course. That might mean debottlenecking the existing process, adding or enlarging vessels, changing shifts, or introducing new buildings. We consider how each option ties into current plant, services and operations, and what it would feel like to run day to day.

-

Visitor offer review & upgrade

Most established distilleries already know their audience. We focus on how to sharpen the offer: reassessing the visitor journey, tour formats, price ladder, use of tasting rooms, bars, shops and outside spaces, and spotting opportunities for new experiences in underused corners of the site. We balance ambition with operational reality – staffing, cleaning, crossover with production and evening use.

-

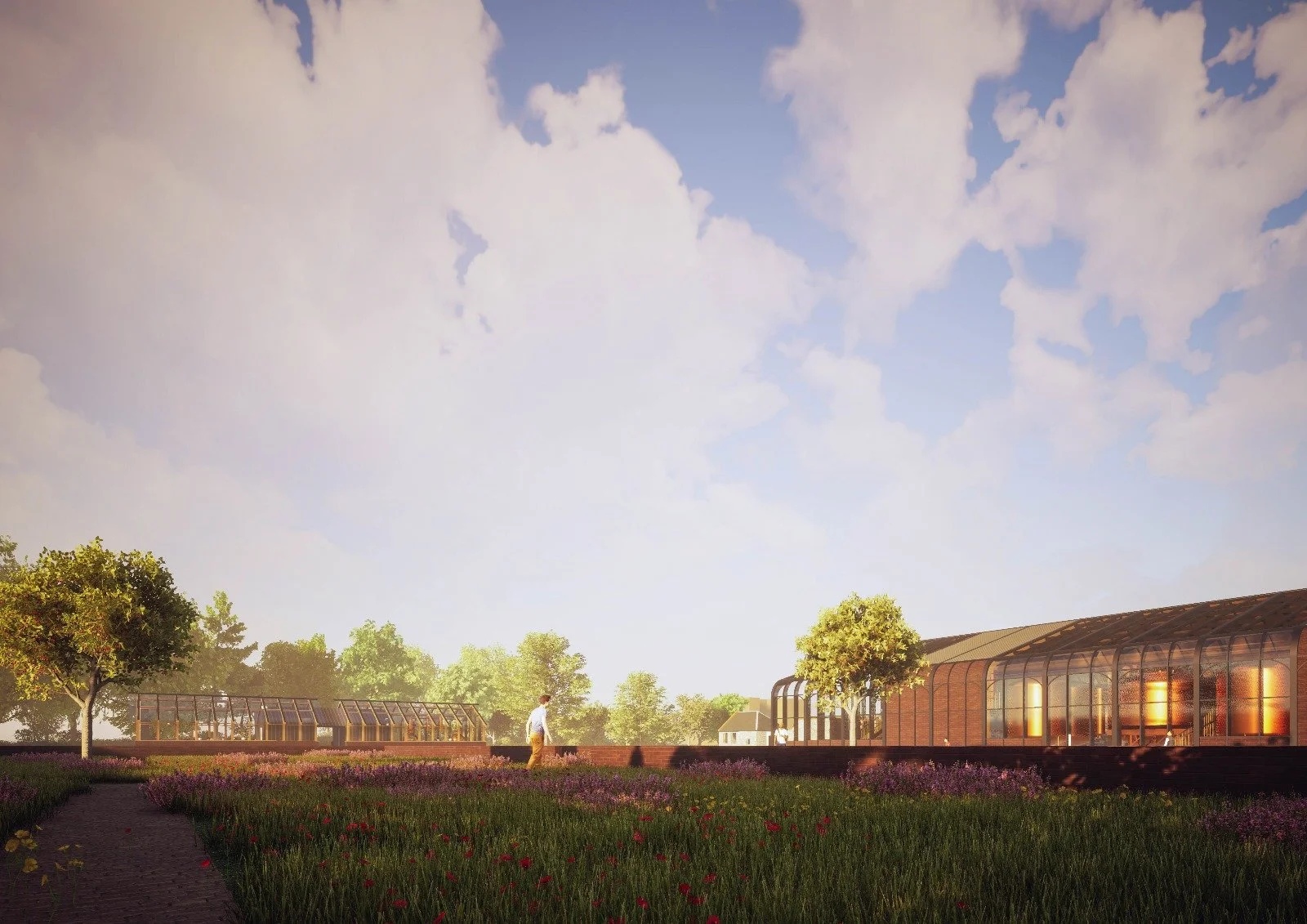

Masterplanning the next phase

We then pull the production and visitor strands back into a single site picture. We set out where new or expanded buildings could sensibly sit, how yards and circulation might be reorganised, and how changes can be phased while you stay operational. We also look ahead, leaving room for potential future phases so today’s decisions don’t box you in.

-

Architecture, character & brand alignment

Architecturally, the aim is evolution rather than reinvention. We consider how new elements talk to the existing buildings in terms of form and materials, where a clearer ‘front door’ might help, and how key visitor touchpoints could be upgraded. Throughout, we look for ways to support your established brand and packaging rather than fighting against them.

-

Sustainability, efficiency & OPEX

For an existing business, some of the biggest wins are operational. We explore targeted improvements to building performance and plant, opportunities for heat recovery and water efficiency, and ways to reduce unnecessary movements for people, forklifts and product. The focus is on practical changes that reduce running costs and headaches.

-

Costs, programme & disruption

Finally, we’re honest about money, time and disruption. We outline order-of-magnitude costs for the main options, compare cost/benefit, and sketch indicative programmes and phasing. Because you’re a live site, we pay particular attention to how works can be sequenced to minimise downtime and risk.

How much does it cost?

How long does it take?

We offer our feasibility studies on a tiered fixed-price basis based around the size of production from Micro/Farm Distilleries up to Production capacity over 5m LPA.

Generally we will work with each clients desired timelines - it’s important to give yourself enough “thinking time” when you are setting the direction of a project so we would recommend three months as a solid guideline.